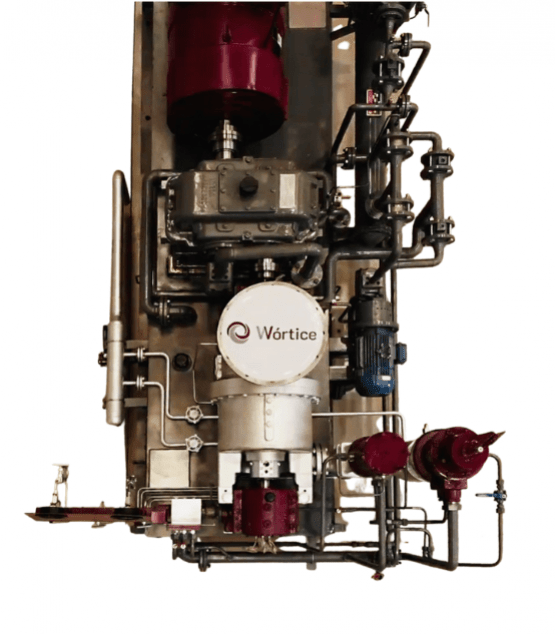

Back Pressure Steam Turbines

Pressure

Steam Turbine

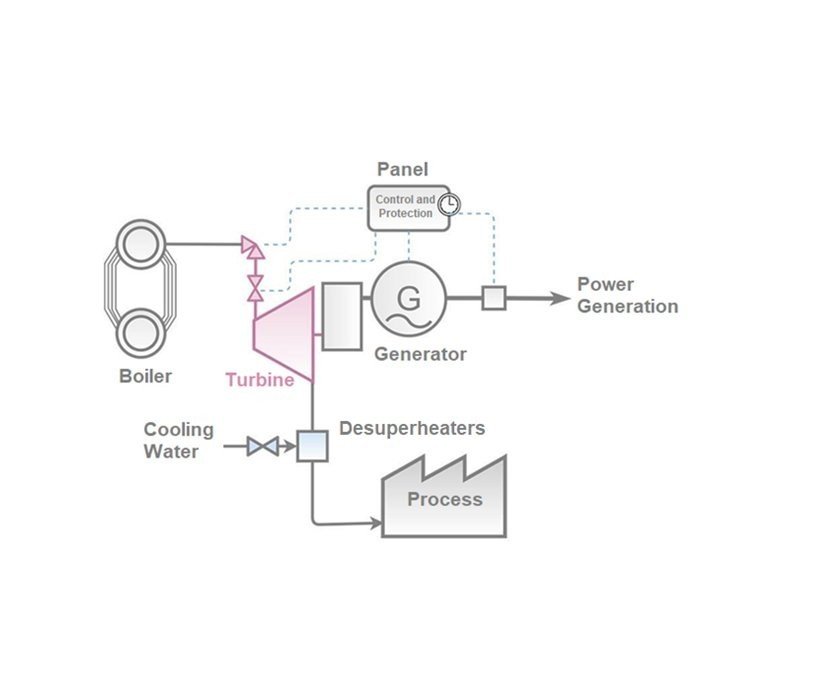

Back pressure turbines are widely used when a continuous steam flow is required for the industrial process. This is a system in which the cycle is not closed. The superheated steam, coming from the boiler, will enter the turbine and will be depressurized by it to the desired pressure for the manufacturing process. The conditions of the exhaust steam used in the process are controlled through the enthalpy fall of the steam used to drive the turbine, thus reaching the ideal conditions for the process.

Flowchart

The steam generated in the boiler under high pressure and temperature is injected into the turbine, where the pressure and temperature will be mechanically lowered by the same condition demanded by the industry.

After leaving the backpressure turbines, this steam, still with a lot of thermal energy, is used in the several processes.

Request a Quotation

Click on the button, fill out the form and we will get back to you shortly.

Request a Quotation

The mechanical work of the turbine makes it to activate the power generator, which, will produce electric energy for the industry.

Back pressure turbines not only drive power generators, but also other equipment and mechanical drives, such as:

- pumps

- compressors

- fans

- mills

- shredders

- Knifes

In which markets can we use Back Pressure Turbine?

Back pressure turbine can be adopted in many industrial facilities where large amounts of steam are required, such as:

- wood companies

- pulp and paper

- fertilizer Industry

- food industries

- breweries

- sugar and alcohol

Wortice Turbines Power Range

| Equipment Model | Power (kW) |

| WX 500 | 200-500 |

| WX 1000 | 500-1000 |

| WX 1500 | 1000-1500 |

| WX 2000 | 1500-2000 |

| WX 2500 | 2000-2500 |

| WX 3000 | 2500-3000 |

| WX 4000 | 3000-4000 |

| WX 5000 | 4000-5000 |

| General Specifications |

|

Rotation (RPM) According to Project Maximum steam inlet pressure bar (a) 42 Maximum steam inlet temperature bar °C 450 Maximum steam outlet pressure bar (g) As the customer needs |

Request a Quotation

Click on the button, fill out the form and we will get back to you shortly.

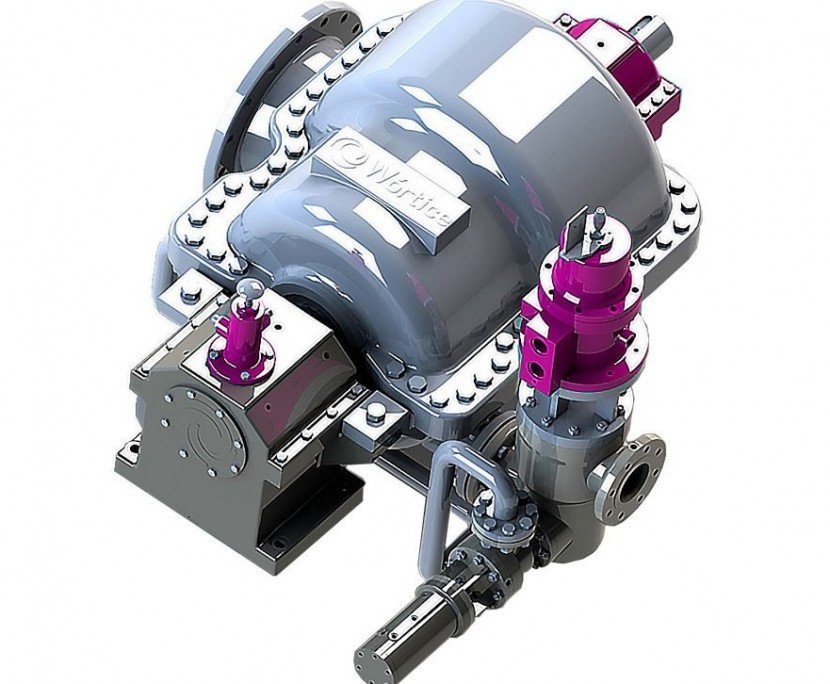

Features of Back Pressure Turbines

- The turbine can be dimensioned so that the steam exhaust has the ideal conditions for application in the process

- Lower investment cost when compared to condensing turbines because no condenser is needed

- Smaller size when compared to condensing turbines

- Lower operating cost

- Greater flexibility regarding boiler feedwater quality

- Back pressure turbines are applied in cogeneration processes, where the thermal energy in the turbine is converted into work and the exhaust steam is in the process with adequate temperature and pressure according to its need, cook, dry, exchange heat, among other possibilities.

When can we choose Pressure Turbines?

Back pressure turbines are indicated in processes where there is a constant consumption of steam, when the industry already has a boiler.

With a pressure above that required in the process, installing backpressure turbines between the boiler and the respective process, the pressure is lowered to the required pressure through the turbine, making it possible to generate thermal and electrical energy with the same steam.

This process is called cogeneration.

Another situation is the industries using equipment that require large powers to operate. So, backpressure turbines can directly drive this equipment, no longer using an electric motor to drive them, and consequently saving electricity.

In addition to it, many industries are installed in remote locations. In this case, the energy generated in this process is the only energy available to the plant, making the industry self-sufficient.

Back Pressure turbines with extraction

Turbines are indicated when two or more different steam conditions are required in the process, at different pressures and temperatures. Process steam at the required pressures is supplied through extraction ports, connected to intermediate stages of the turbine. Power generation depends on the steam demand of the process.

Request a Quotation

Click on the button, fill out the form and we will get back to you shortly.

Request a Quotation